A Certified Woman owned Business Enterprise (WBE) and A Certified Minority owned Enterprise (MBE)

Services Provided

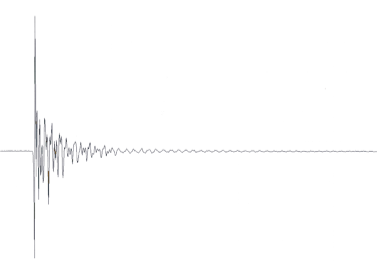

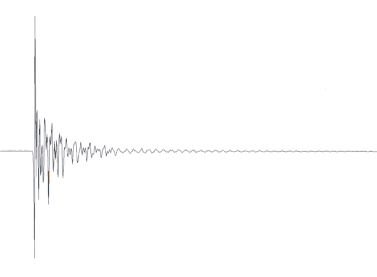

Vibration Monitoring and Analysis:

Vibration Monitoring and Analysis services can be performed on a scheduled basis so the equipment health and reliability can be assessed. This information can then be used to schedule equipment maintenance requirements. Scheduling maintenance when required is the goal of this service.

Alarms will be set for each piece of equipment based on equipment design and importance of the equipment to the system. No generic alarms provided by software vendors will be utilized. Alarms will be developed for each band setting in the spectrum plots.

The equipment databases will be developed specifically for each piece of equipment. No generic setups provided by software vendors will be utilized. The following contains the basis for the Delaware Analysis Services, Inc database development. Bandwidth parameters will be setup for each data point so as to be able to separate important frequencies out of the overall vibration amplitudes. This is important since it is possible to have no overall vibration alarms; however, individual frequency problems (i.e. bearing defect frequencies) can be masked by high amplitude frequencies (i.e. gearmesh, 1X vane and blade pass).

Wireless Vibration Monitoring and Analysis:

Delaware Analysis Services, Inc can work with our vendors and develop a wireless monitoring system that when installed can collect and trend vibration amplitudes on a scheduled basis from every 10 minutes to once per day. This data is automatically stored on a plant computer or sent directly to our offices for analysis and review. These systems automatically advise via email, cell phone or warning light of problems.

Vibration Analysis: Analysis of vibration based problems can be provided on-site or recorded for analysis back at our office. Our equipment consists of multi - channel tape recorders, multi-channel analyzers and modal analysis equipment. Pickups utilized are accelerometers, velocity pickups or proximity probes. Delaware Analysis Services has experience working on both simple problems (Balance, Alignment and Mechanical Looseness) and the advanced problems of Oil Whirl, Oil Whip and Resonance.

Balancing: Single, Dual Plane or Multi-Plane balancing services can be provided. Delaware Analysis has experience balancing all types of equipment from turbine/generators, motors, pumps and fans to vibrating parts feeders. Balance histories are stored in a computer program so the data can be referenced in the future for cross influence coefficients limiting the number of balance runs required.

Modal and Rotordynamic Analysis: Modal analysis can be provided with our multi-channel analyzers utilizing impact hammers or operating data. In addition, we can model the structure or rotating system and do a design natural frequency analysis. Three modeling programs are utilized: two are forced response types and the other is for critical speed analysis.

Motor Current Analysis: Utilizing a current transformer connected to a lead for a motor amp meter, an evaluation of the rotor bar and stator condition can be assessed. This test can evaluate the long term condition of plant motor rotor bars and stators.

Prognostics and Life Assessment: Utilizing various collected data and developed algorithms equipment remaining life and failure modes can be assessed for clients to project remaining asset life. This provides a solid foundation for asset management.

Vibration Monitoring System Design: Technical assistance and engineering is provided, in the planning stages, to help choose the equipment to best provide protection against failure. Design of systems utilizing prox probes and accelerometers can be provided. Systems can be designed for protection, analysis or both. All the engineering drawings are provided; along with working with the client machine shop building required brackets and making equipment modifications for the installation of probes.

Training: Training can be provided in house on your schedule. Attached is a list of the classes provided or we can develop specific classes to fit your requirements. Delaware Analysis Services, Inc also provides Vibration Institute ISO Vibration certification Classes covering ISO Category I, ISO Category II, ISO Category III and ISO Category IV Classes. We can also provide the ISO Certification Exams.

Oil Monitoring and Analysis: Through a third party oil analysis services can be provided to look at oil cleanliness and condition. This is quoted directly through our oil partner.

Infrared – Thermography Services: Through a third party thermography services can be provided to look for “hot” electrical connections and motor faults. This is quoted directly through our infrared partner.

Home

Services Provided

Clients

Equipment

Training

Biography

Published Articles

Contact Us